Application

New Parametric Current Transformers are used on most particles accelerators in the world to measure the average beam current.

They are essential instrument for machine tuning, commissioning, operation and machine/personnel safety.

The large dynamic range, the wide bandwidth and high resolution make it the ideal instrument to measure beam lifetime in storage rings.

It is often the only truly calibrated beam instrument in an accelerator and serves as a reference to calibrate other beam diagnostics.

Main features

- Full Scale Range ±20 mA, ±200 mA, ±2 A and ±20 A

- Resolution down to 0.5 µA rms/√(Hz)

- Output Bandwidth from DC to 10 kHz (-3dB)

- Linearity error ≤ 0.1 %

Downloads

Datasheets

User's manual

Papers

Technical Drawings

In-air

In-flange

- NPCT-CF2''1/8-22.2-120-UHV

- NPCT-CF2''3/4-34.9-120-UHV

- NPCT-CF3''3/8-38.0-120-UHV

- NPCT-CF4''1/2-47.7-120-UHV

- NPCT-CF4''1/2-60.4-120-UHV

- NPCT-CF6''-96.0-120-UHV

- NPCT-CF8''-147.6-120-UHV

- NPCT-CF10''-198.4-120-UHV

Current price list

2 packaging types for the NPCT sensor

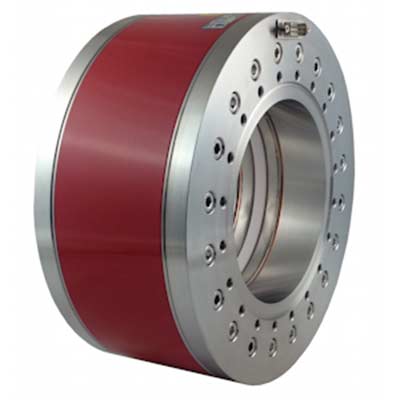

In-flange NPCT

In-flange NPCT is mounted in the beam line.

Short axial length (120 mm), includes a ceramic gap vacuum-brazed to kovar.

Does not require bellows nor wall current bypass

Material AISI-304, 316LN on option

Available from CF2“1/8 to CF108“

UHV compatible

In-air NPCT

In-air NPCT installation, over the vacuum chamber. Requires installation of a “gap” to prevent the wall current from flowing through the NPCT aperture.

The gap can be a brazed ceramic ring or an organic material O-ring depending on the vacuum requirements.

Typical installations include bellows, a wall current bypass and an electromagnetic shield enclosing the NPCT completely.